It’s incredible to think that our trusty smartphones, lifesaving pacemakers, and eco-friendly electric cars wouldn’t have stood a chance just a few decades ago. This revolution has come about thanks to, among other things, lithium-ion batteries. While these batteries have driven progress, they are not without their limitations. The finite availability of their materials poses a looming supply challenge, particularly amid the escalating push for the electrification of vehicles.

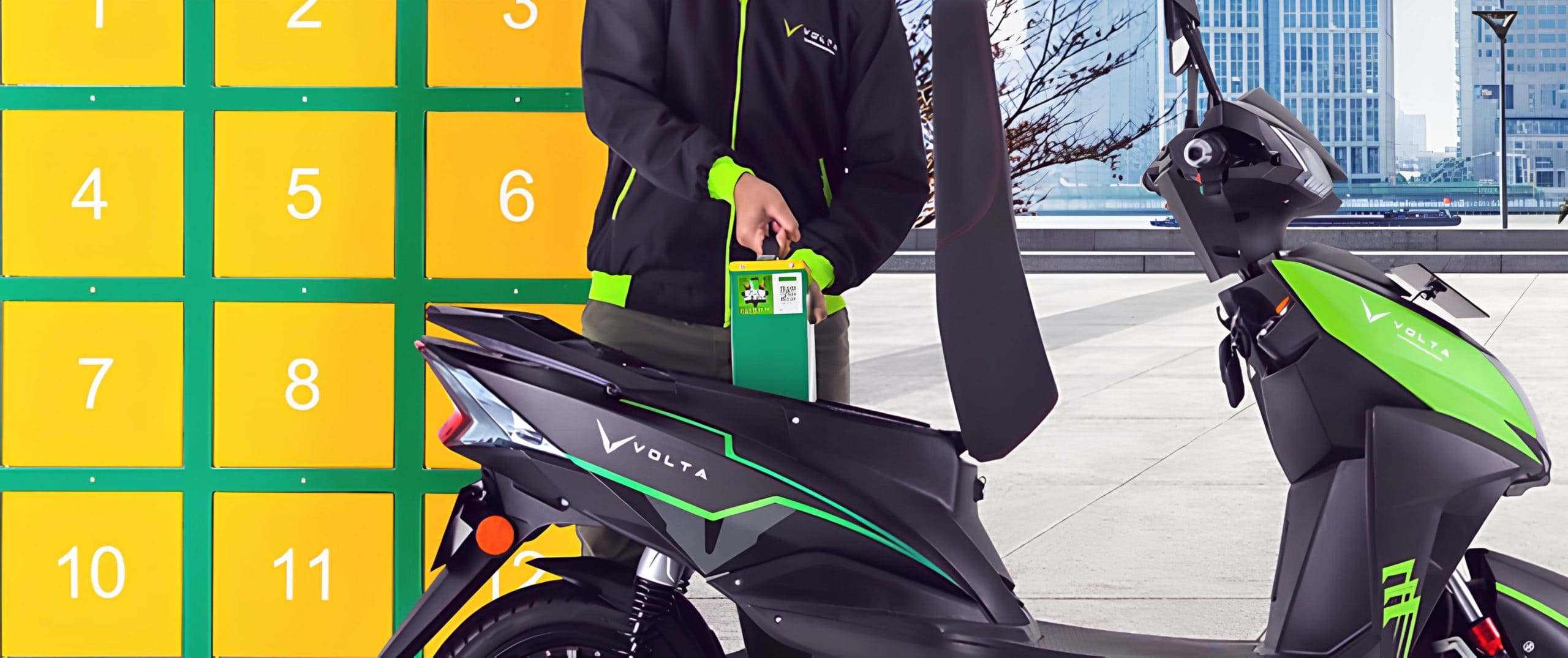

The lack of a comprehensive recycling ecosystem for used batteries exacerbates the problem, leading to considerable waste of these vital materials, contributing to the depletion of resources and increasing environmental pollution. Hence, we at TTV believe that a pioneering battery recycling technology will be crucial in supporting the global shift to electric mobility and Green Li-ion fits perfectly into our mission to enable electric vehicle (EV) industry to reduce reliance on supply from mining operations and removing future contributions of spent lithium ion to landfill. The battery recycling market is growing at a 34% CAGR in the next decade and here are among the reasons why Green Li-ion is set to play a vital role:

Battery chemistry agnostic

To achieve sustainability, we must give way to circular economy where metals are recycled. Green Li-ion’s hydrometallurgy and co-precipitation technology can fully rejuvenate all types of lithium-ion batteries, ultimately putting an end to the wasteful disposal of 95% of spent batteries, while delivering yield outputs that are 4x more valuable compared to black mass.

One of the key features of this technology is its battery chemistry agnostic nature, which means it can accept black mass input from a wide range of major battery chemistries. Whether you’re dealing with nickel manganese cobalt (NMC), lithium cobalt oxide (LCO), lithium nickel cobalt aluminium oxide (NCA), or lithium titanate batteries (LTO), Green Li-ion has the adaptability to handle them all. This capability allows for a faster recycling process than traditional methods as it eliminates the need for the sorting of black mass.

Plug and play

What sets Green Li-ion apart is its ability to provide highly controllable and customizable outputs, bypassing conventional process of production of mixed precious metal salts, to directly produce various battery-grade pre-cursor Cathode Active Materials (“pCAM”). This versatile technology is designed with modularity in mind, making it easy to integrate into existing battery recycling facilities with minimal adjustments, essentially a “plug and play” solution.

The A-team

Introducing the visionary co-founders behind Green Li-ion: Leon is a seasoned entreprenuer, having successfully scaled energy firms globally, and serves on the boards of several energy startups.

Meanwhile, Reza brings a wealth of industry knowledge in hydrometallurgical processing of Lithium-ion batteries, backed by a PhD in Environmental Engineering from the National University of Singapore. With over 40 published works boasting 2,200 citations, he’s even contributing a chapter on E-waste Management for ‘Circular Economy and Sustainability: Solid Waste Management’. Together, they form the dynamic duo driving Green Li-ion’s innovative journey.